Types of printing

Offset lithography

Offset printing is a commonly used printing technique in which the inked image is transferred (or "offset") from a plate to a rubber blanket, then to the printing surface. When used in combination with the lithographic process, which is based on the repulsion of oil and water, the offset technique employs a flat (planographic) image carrier on which the image to be printed obtains ink from ink rollers, while the non-printing area attracts a water-based film (called "fountain solution"), keeping the non-printing areas ink-free.

Development of the offset press came in two versions: in 1875 by Robert Barclay of England for printing on tin, and in 1903 by Ira Washington Rubel of the United States for printing on paper.

http://en.wikipedia.org/wiki/Offset_printing

Rotary printing

A rotary printing press is a printing press in which the images to be printed are curved around a cylinder. Printing can be done on large number of substrates, including paper, cardboard, and plastic. Substrates can be sheet feed or unwound on a continuous roll through the press to be printed and further modified if required (e.g. die cut, overprint varnished, embossed). Printing presses that use continuous rolls are sometimes referred to as "web presses". Rotary drum printing was invented by Richard March Hoe in 1843, perfected in 1846, and patented in 1847. (Note – Some sources describe Parisian 'Hippolyte Auguste Marinoni', (1823, 7 January 1904) as the inventor of the Rotary printing press).

Today, there are three main types of rotary presses; offset including web offset, rotogravure, and flexo (short for flexography). While the three types use cylinders to print, they vary in their method.

http://en.wikipedia.org/wiki/Rotary_printing_press

Web 'offset' machine

Web offset is a form of offset printing in which a continuous roll of paper is fed through the printing press. Pages are separated and cut to size after they have been printed. Web offset printing is used for hi heatset gh-volume publications such as mass-market books, magazines, newspapers, catalogs and brochures. There are two methods of web offset printing, known as heatset and coldset (or non-heatset). In the heatset process, the ink is dried rapidly by forced-air heating. In the non-or coldset process, the ink dries more slowly by ordinary evaporation and absorption.

http://whatis.techtarget.com/definition/web-offset-printing

Rotogravure

Rotogravure (Roto or Gravure for short) is a type of intaglio printing process; that is, it involves engraving the image onto an image carrier. In gravure printing, the image is engraved onto a cylinder because, like offset printing and flexography, it uses a rotary printing press. Once a staple of newspaper photo features, the rotogravure process is still used for commercial printing of magazines, postcards, and corrugated (cardboard) product packaging.

http://en.wikipedia.org/wiki/Rotogravure

Flexography

Frequently used for printing on plastic, foil, acetate film, brown paper, and other materials used in packaging, flexography or flexographic printing uses flexible printing plates made of rubber or plastic. The inked plates with a slightly raised image are rotated on a cylinder which transfers the image to the substrate. Flexography uses fast-drying inks, is a high-speed print process, can print on many types of absorbent and non-absorbent materials, and can print continuous patterns (such as for giftwrap and wallpaper). Some typical applications for flexography are paper and plastic bags, milk cartons, disposable cups, and candy bar wrappers. Flexography printing may also be used for envelopes, labels, and newspapers.

http://desktoppub.about.com/cs/printing/g/flexography.htm

Digital printing

Digital printing refers to methods of printing from a digital based image directly to a variety of media. It usually refers to professional printing where small run jobs from desktop publishing and other digital sources are printed using large format and/or high volume laser or inkjet printers. Digital printing has a higher cost per page than more traditional offset printing methods but this price is usually offset by the cost saving in avoiding all the technical steps in between needed to make printing plates. It also allows for on demand printing, short turn around, and even a modification of the image (variable data) with each impression. The savings in labor and ever increasing capability of digital presses means digital printing is reaching a point where it could match or supersede offset printing technology's ability to produce larger print runs of several thousand sheets at a low price.

http://en.wikipedia.org/wiki/Digital_printing

Screen printing

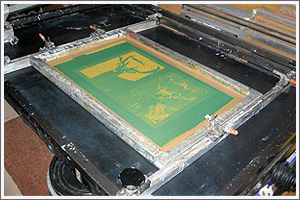

Screen printing is a printing technique that uses a woven mesh to support an ink-blocking stencil. The attached stencil forms open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edged image onto a substrate. A fill blade or squeegee is moved across the screen stencil, forcing or pumping ink into the mesh openings for transfer by capillary action during the squeegee stroke.

Screen printing is also a stencil method of print making in which a design is imposed on a screen of polyester or other fine mesh, with blank areas coated with an impermeable substance, and ink is forced into the mesh openings of the mesh by the fill blade or squeegee and onto the printing surface during the squeegee stroke. It is also known as silkscreen, serigraphy, and serigraph printing. A number of screens can be used to produce a multicoloured image.

http://en.wikipedia.org/wiki/Screen_printing

PAD printing

Pad printing utilizes a flexible silicone rubber transfer pad that picks up a film of ink from a photo-etched printing plate and transfers it to a three-dimensional part surface. The unique properties of silicone rubber allow distortion-free, single or multi-color images to be applied to flat, curved, or tapered surfaces with excellent definition and opacity. Pad printing inks, specifically formulated to adhere to various substrates, are used to decorate metals and ceramics as well as a wide range of of plastics. Ink viscosity is controlled by use of a closed-cup ink reservoir, which is moved over the etched plate by the printer’s mechanism. For multi-color decorating, two or more pads may apply additional images and colors to the part, while accurate image registration is maintained throughout the printing cycle. This precise repeatability also permits application of the same image for increased opacity. Fully automatic, high-volume pad printing systems may include surface pre-treatment, part handling and orientation, ink curing, and other auxiliary equipment.

http://www.itwdecorating.com/ITW_PP.htm

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the cliché via a silicone pad onto a substrate. Pad printing is used for printing on otherwise impossible products in many industries including medical, automotive, promotional, apparel, and electronic objects, as well as appliances, sports equipment and toys. It can also be used to deposit functional materials such as conductive inks, adhesives, dyes and lubricants.

http://en.wikipedia.org/wiki/Pad_printing

No comments:

Post a Comment